When Hiway Model Gifts Co., Ltd decided to create die-cast models, our goal was to put together the most advanced manufacturing techniques.

Diecast Model Production Process

1.Project description: Hiway should know the detailed description of your project like the model name, model scale, material, quality level, function&features,quantity, packaging details,etc...this will be a key effect in quotation.

2. Photos and drawing collection: the detailed pictures, dimension and equip 3D data are very important in high quality diecast model project, please get those information as much as possible, and we will make a detailed quotation based on above information you provided,for example mold quantity, 3D design cost, mold cost, unit cost, etc.

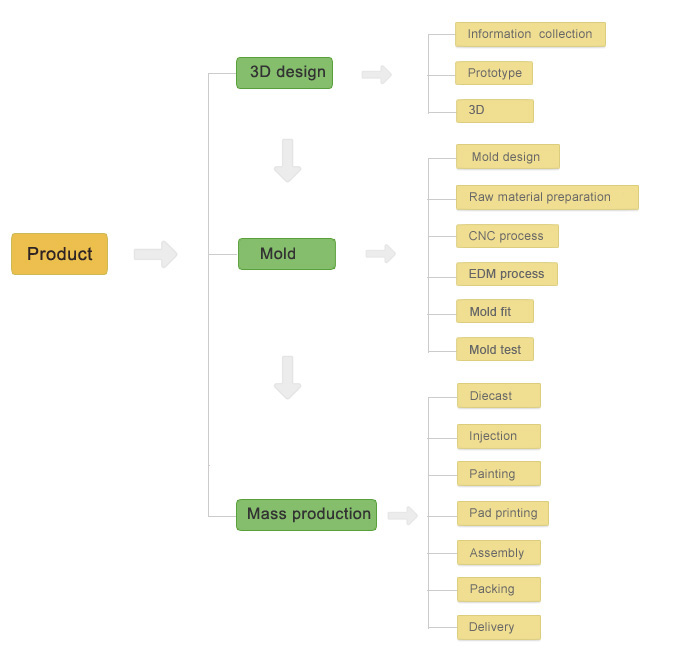

3.Product 3D design: we will design the product 3D based on pictures, 3D drawing of real machine and description, we will show all the product details and function on 3D, the 3D will sent to customer for approval or modification, this would be a key step for high quality scale model manufacturing, 3D design will take about 25-30 days.

4.Mold design, tooling&mold production: after 3D drawing confirmed, we move to mold design, tooling and mold production, this step will take about 45 days up to the details and quality of the model. At Hiway, our factory equip full facilities for tooling&mold production, and our experienced mold engineer team have more than 10 years in mold design and mold production which make sure we offer our customer high quality products.

5.1st shot sample&mold modification: after mold production, we will release the 1st shot sample in 7 days, our engineer team will check this sample firstly to see if all parts and details meet our design and production requirement, and we will send this sample to our customer for approval, the refined 2nd shot sample will be released after 10 days according to the feedback and comments from our customer.

6.2nd shot sample&packaging: we will make the 2nd shot sample with full painting and packaging,2 or 3 sets samples will be sent to our customer for final approval, 1 set sample should be sent back to factory with signature if everything is ok or re-modify the sample till customer’s final confirmation as pre-production sample.7.mass production prepare at approved pre-production sample.

7.Mass production: after the confirmation of pre-production sample and packaging, we will get this signed back sample as quality standard to start mass production,. The procedure of mass production be listed as below: Diecast&injection, surface processing, spraying, pad printing, final assembling, QC and packing.

8.Final quality inspection&Shipping: We asking for final quality inspection by your QC after the full production finished, the 100% passed cargo will be stored in warehouse and waiting for shipping, by air or by sea.